Supply chain disruptions, geopolitical tensions, economic pressures, labor shortages and escalating costs have all served to refocus the industry on the issues of risk and resilience. An industrywide imperative to work smarter, more aligned and more efficiently has become the norm.

One thing is for sure: to stay ahead and remain competitive, logistics companies will need to adapt swiftly to the latest technological trends. This allows them to stay ahead of the curve and work towards a more agile and reliable future.

With this in mind, let’s take a look at the top developments and innovations set to shape the logistics sector in 2025. Or learn more about our fleet management software capabilities.

1. Digitalization

Logistics operators are investing heavily in digital technologies that will increase the productivity of their warehouse and transportation networks, generate cost efficiencies, and enable sustainable change over time. For many that means building on existing Internet of Things (IoT) investments to enable the real-time tracking of assets and vehicles alongside enhanced inventory management capabilities and greater supply chain visibility.

In the world of logistics, digitalization is proving to be a game changer that’s enabling firms to streamline processes for maximum efficiency and meet the growing demand for environmentally friendly practices.

Thanks to advanced cloud-powered software solutions, today’s companies can manage their supply chains with pinpoint precision, using smart digital tools to undertake everything from inventory management to route planning and the delivery of real-time customer updates every step of the way. This also enables logistics firms to progress their sustainability agenda and reduce their carbon footprint by optimizing transport routes and using connected IoT devices to monitor and control energy consumption in warehouses and distribution centers.

In 2025, internal and external supply chains will become increasingly integrated. This development will allow logistics firms to better detect and respond to changes in demand as they happen. In doing so, they can manage their day-to-day operations, such as flow and resource monitoring, far more effectively.

Finally, product tracking technologies are set to grow in sophistication in 2025, opening the door to shorter delivery times, faster localization of items, increased competitiveness, and greater customer satisfaction.

2. Automation

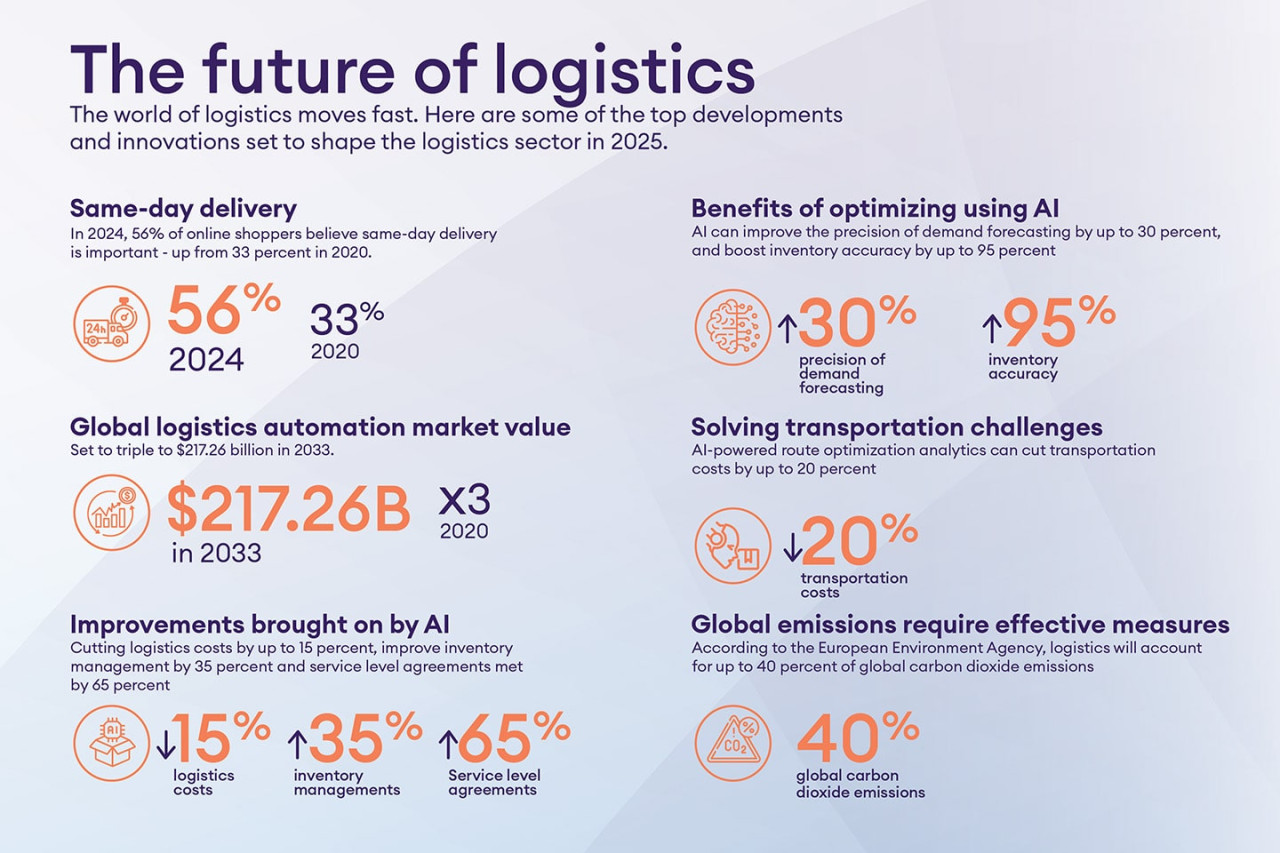

Logistics firms are increasingly juggling two key challenges. On the one hand, labor shortages are impacting how quickly products are picked, packed, shipped and delivered. On the other hand, demand for same-day delivery is on the rise, with 56 percent of online shoppers believing same-day delivery options are important – compared to 33 percent back in 2020.

To address these challenges and adapt to everchanging market needs, logistics firms are harnessing automation technologies, such as workflow automation. This helps them increase their operational throughput at limited costs, while improving their service delivery capabilities.

In 2025, automation solutions will move center stage as logistics firms increase their investment in robotics, autonomous mobile robots, warehouse drones and automated guided vehicles that can handle repetitive tasks such as picking, packing, and sorting. Similarly, automated storage and retrieval systems will be used to optimize the use of warehouse space and improve storage density and retrieval times. When these automated systems are integrated with supply chain systems, logistics firms will be able to operate more efficiently, minimize errors, and better meet the demands of today’s dynamic markets.

With the global logistics automation market set to more than triple to hit USD 217.26 billion by 2033, organizations will need to train their human workforces in readiness for working alongside automation technologies. Doing so will ensure the seamless human-machine interactions that generate higher productivity.

3. Artificial Intelligence (AI) and Machine Learning (ML)

The value creation potential of AI and ML in logistics is immense and more and more organizations are preparing to apply these technologies to streamline their logistics procedures, improve efficiency and reduce wastage resulting from human error.

Research by McKinsey found that the successful implementation of AI has helped companies cut logistics costs by 15 percent, achieve a 35 percent improvement in inventory management and a 65 percent increase in service level agreements met. As AI and ML technologies continue to advance, their influence on optimizing logistics and all related support processes is only set to grow.

For example, AI-driven predictive modelling and real-time monitoring can improve the precision of demand forecasting by up to 30 percent. Furthermore, AI can automatically adjust inventory levels based on real-time data and boost inventory accuracy by up to 95 percent.

In the warehouse, inventory tracking can be automated using AI cameras and sensors that reduce human error. AI can also be leveraged in warehouse and distribution centers to precisely determine the best position for assets in relation to demand patterns, transportation networks and labor availability at individual locations.

When it comes to last mile planning, AI algorithms can consider traffic conditions, vehicle characteristics and delivery windows to optimize routes for both linehaul and last-mile deliveries. This will both reduce fuel consumption and delivery times while elevating customer satisfaction. Indeed, AI-powered route optimization analytics can cut transportation costs by up to 20 percent.

4. Sustainable logistics

The European Environment Agency predicts that logistics will account for up to 40 percent of global carbon dioxide emissions by 2050 unless effective measures are taken. While the industry is no stranger to the issue, more and more firms are proactively viewing sustainability as a force for positive change. By spotting and addressing inefficiencies, they will be able to save money and reduce emissions. Plus, they will be better prepared to deliver against customer expectations in relation to the provision of reliable compliance data.

In 2025, sustainability strategies will be targeted at transforming operational performance. For example, adopting sustainable dynamic order management and fulfillment technologies and gaining real-time insights across fulfillment networks so they can provide a flexible choice of customized delivery options – including green fulfillment options and batched deliveries at convenient pick-up points. Plus, they’ll be leveraging real-time data to extend the lifetime of their fleet assets.

Besides switching to electric vehicles and optimizing transport routes and vehicle capacity to reduce emissions, logistics companies will be implementing smarter warehousing systems that identify where operational inefficiencies and bottlenecks are costing the business. They’ll also be looking to initiate innovative reverse logistics strategies that support a circular economy model.

To drive these innovations and optimize operations in a way that boosts sustainability and efficiency will, however, require connectivity, cloud computing, advanced data analytics and more.

Towards a brighter future

Significant advancements in technology are revolutionizing logistics processes. From automation that boosts productivity and workflow efficiency through to real-time transparency and traceability in supply chains that support more agile and flexible operations. SaaS technologies have made innovative tools and specialist solutions accessible industrywide, meaning more companies than ever can leverage cutting-edge logistics technologies to improve their competitive stance.

As we approach 2025, these changes are set to accelerate. From predictive analytics and demand forecasting through real-time visibility and AI and ML that supports logistics and innovations in last-mile delivery, the race is on to initiate more resilient logistics operations. The logistics company of the future has a clear focus on optimizing speed, cost-efficiency and sustainability across distribution, fulfillment and delivery.

Frequently Asked Questions

If your organization utilizes capital-intensive assets, IFS Ultimo's best-of-breed EAM is an invaluable tool for optimizing your asset management. Ultimo excels in manufacturing, logistics, healthcare, infrastructure and utility sectors.

-

Do you have capital-intensive assets? Then an EAM system is an invaluable tool for optimizing their management. Ultimo is well represented in the manufacturing, logistics, healthcare, infrastructure and utility sectors. View our cases.

Latest resources

Request a demo

Get your questions answered. Schedule a personalized demo to see how Ultimo can add ease and value to your business. No strings attached.